Products Center

Second plate

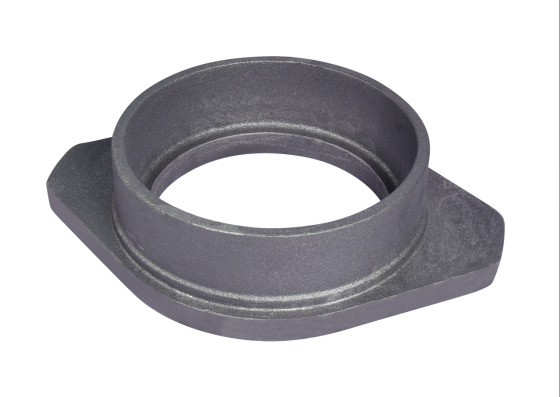

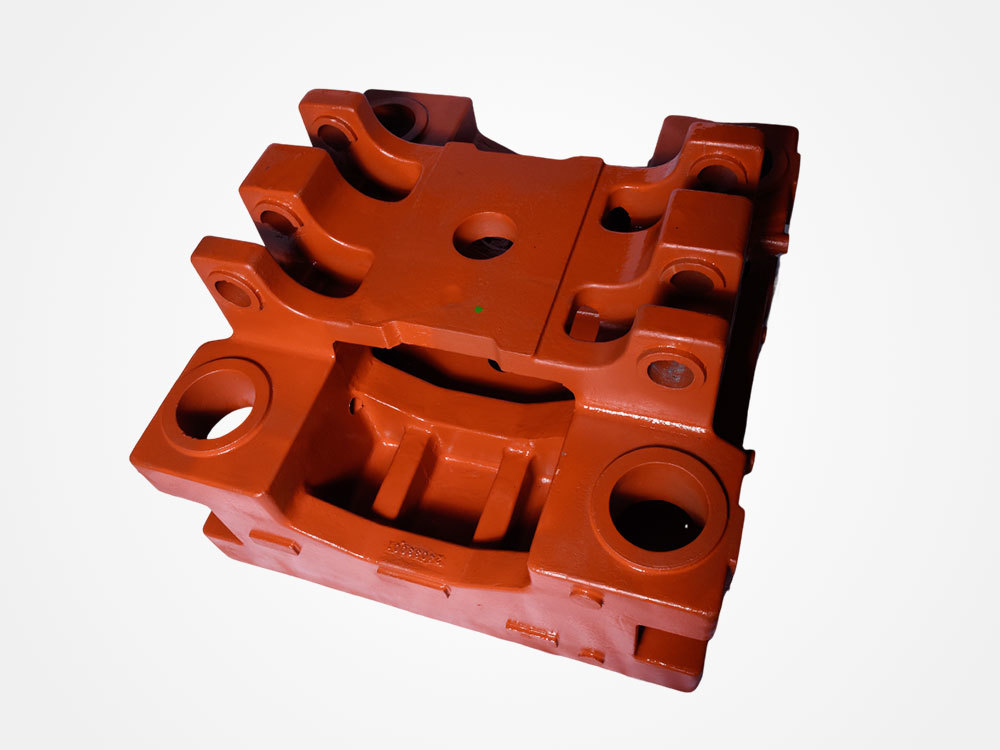

Casting structure design: ensure its working performance and mechanical performance requirements, consider the requirements of casting process and alloy casting performance on casting structure, and whether the casting structure design is reasonable or not has a great impact on the quality, productivity and cost of castings.

Product Category: Casting Industry Department

Keywords: Forging, Hetai

Tel: 0575-85529660

Email: shaoxinghetai@163.com

Product Details

Shaoxing Hetai Machinery Technology Co., Ltd. is equipped with 6 iron mold sanding lines, and the sand box sizes are 1050X1200 and 800X1350. It can produce high-quality castings made of QT400-15, QT450-10, QT500-7, QT600-3, QT700-2, HT250, and HT300 materials. It has an annual production capacity of 6,000 tons of castings, which is particularly suitable for producing high-quality castings with no shrinkage, no leakage, stable dimensions and beautiful appearance.

- Meet the strength and stiffness requirements. For box parts that are subject to great forces, meeting the strength requirements is an important issue; but for most boxes, the main indicator for evaluating performance is stiffness, because the stiffness of the box not only affects the normal operation of the transmission parts, but also affects the working accuracy of the components. It is included in the automatic selection of casting parts.

- Heat dissipation performance and thermal deformation issues. The friction and heat generated by the parts in the box changes the viscosity of the lubricating oil, affecting its lubrication performance; the increase in temperature causes thermal deformation of the box, especially the thermal deformation and thermal stress caused by uneven temperature distribution, which have a great impact on the accuracy and strength of the box.